Our Process

-

Our strength in producing the goods without any compromise on quality.we design the production products in the sampling department itself with the easy method, this will be explained to end sewing person with the help of product engineering team.our efforts are directed towards devising new methods of quality checks while still adhering to stringent standards.for higher productivity and cost effective we have implemented lean management system and 5s.

Raw materials and fabric accessories are checked thoroughly at source for consistency in shades, shrinkage, and width. a pre-production meet is held to ensure required machineries are deployed to meet production targets and quality standards. this is augmented by an inline, midline and final inspection system. the final product is inspected by a quality team which is aptly trained and ensures product standards are maintained as per aql 2.5/4 or as specified by client.

-

DEVELOPMENT & SAMPLING

We have in-house sampling unit which is fully equipped with required machineries, headed by competent masters and technicians. Samples are developed as per styles and specification within the shortest possible time. To achieve these we maintain stock of various fabrics and aim to deliver within three days. Samples developed are checked for specifications and are put on dummies for fit-up trials.

CAD/CAM PATTERN MAKING

The department is manned by competent pattern makers who carryout development, pattern grading and marking, using cad softwares and we have automatic pattern cutting machine.

-

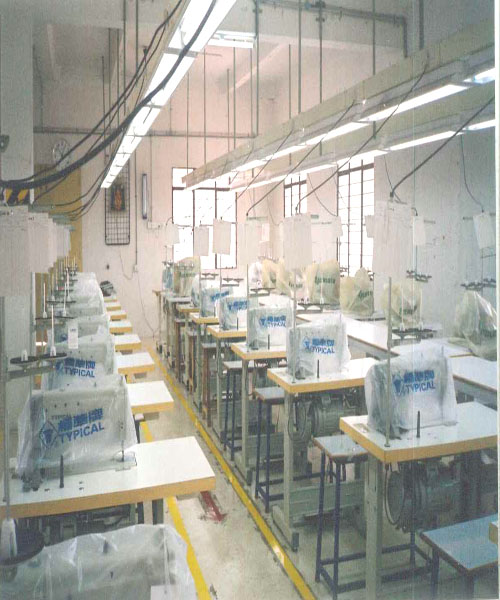

Our production unit in TIRUPUR is SA 8000 compliant,DISNEY and is equipped with advanced machinery and state-of-the art facilities. A thoughtful lay out of modern specialized machinery on a working area of 20,000 sq. ft helps us churn out 75,000 pieces a month.

Computerized UBT machines, Button machines, Button-hole machines, ARE used to achieve quality as well as quantity. The unit is also equipped with pneumatic Snap Button machines, Spot removing units, and Fusing machines. All these virtues give us the flexibility to deploy enough resources and execute orders without any constraints.

-

EXPERTISE

Ensembles, Blouses, Dresses, Skirts, Ladies Blouses, T-Shirts, Zipper, Pyjamas, Nightwears, Pullovers, Cardigans, Sweat Shirt, Babies Garments, and Track Suits. We specialise in handling sequence and beaded garments and have a good facility of sourcing sequence material from India and abroad. The company is having a very strong Production knowledge in knitting, dyeing, printing, washing. -

SAMPLING

Swatch cards provided for new design colour & sketch development.Production Age Groups

0 – 24 Months, 3 Years to 16 Years, S.M.L & XL.Order Status

Production Status Report issued periodically. -

Factory Area

Unit – A --- 10000 sq. ft.

Unit – B --- 10000 sq.ft.

Unit – C --- 5000 sq.ft.

Total:-25000 sq.ft -

FABRIC USED

Winter – Terry, Jacquard, Rib, Interlock Jacquard, Polar Fleece, Sherpa, Velour, Fleece; Summer – Interlock, Single Jersey, Rib 1x1, Drop needle etc.Materials Used

0 – 24 Months, 3 Years to 16 Years, S.M.L & XL.Order Status

Production Status Report issued periodically.

Other Details

Our production unit in TIRUPUR is SA 8000 compliant,DISNEY and is equipped with advanced machinery and state-of-the art facilities. A thoughtful lay out of modern specialized machinery on a working area of 20,000 sq. ft helps us churn out 75,000 pieces a month.

Computerized UBT machines, Button machines, Button-hole machines, ARE used to achieve quality as well as quantity. The unit is also equipped with pneumatic Snap Button machines, Spot removing units, and Fusing machines. All these virtues give us the flexibility to deploy enough resources and execute orders without any constraints.

Additionally, the unit is laid out as per compliance requirements of international standards. The floor is equipped with fire-fighting equipments and has enough passage and ventilation facility.